With the innovation of Mini & Micro LED products and the expansion of market share, the mainstream technology competition between COB and MIP has become "fiercely competitive." The choice of packaging technology has a crucial impact on the performance and cost of Mini & Micro LED.

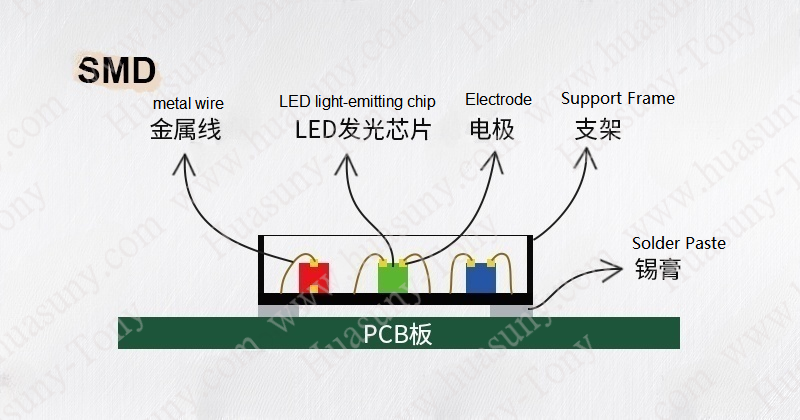

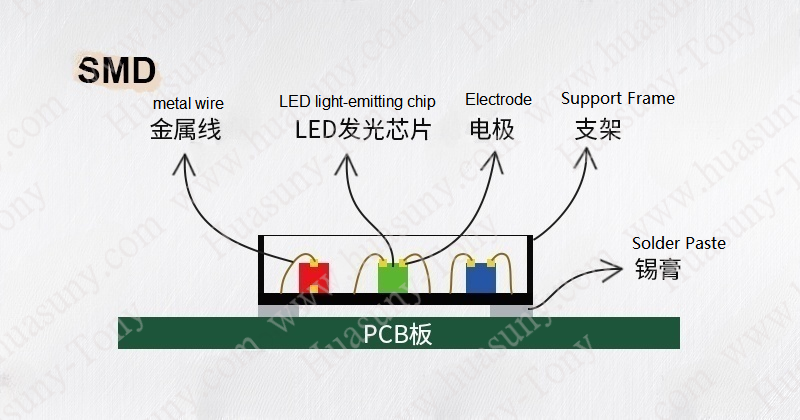

What is SMD?

The traditional SMD technology route involves packaging one red, one green, and one blue (RGB) light-emitting chip into a single LED, and then using SMT solder paste to weld it onto a PCB board to form a unit LED tile/module, which is finally assembled into a complete LED screen.

SMD

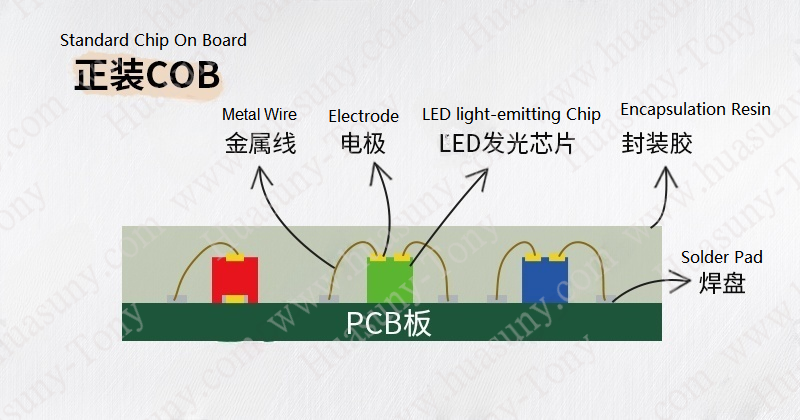

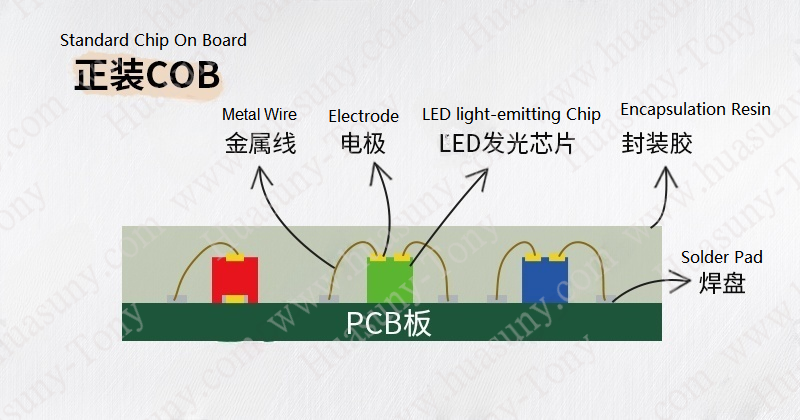

What is COB?

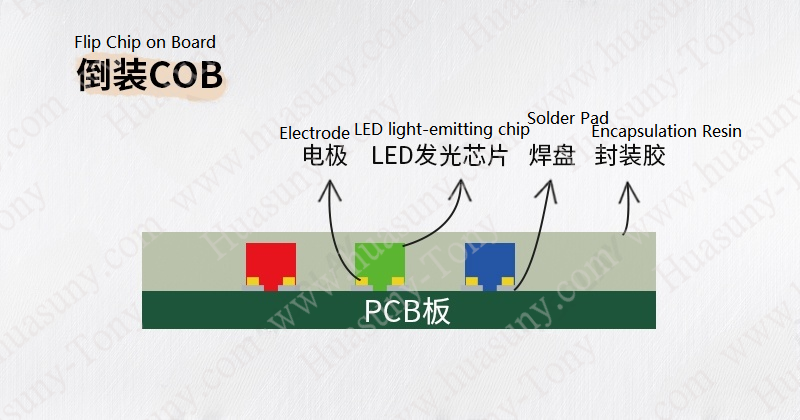

COB stands for Chip on Board, which refers to directly welding multiple RGB chips onto a single PCB board, by a one-piece film encapsulation to form a unit module, which is then assembled into a complete LED screen.

Conventional COB

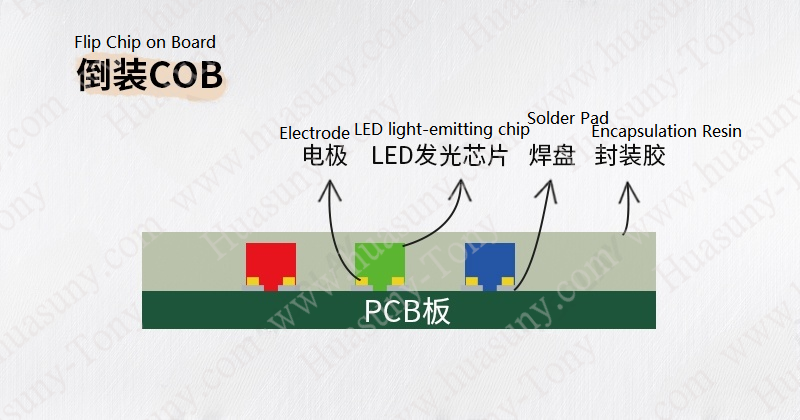

COB packaging comes in two forms: Standard and Flip. The light-emitting angle and wire bonding distance of Standard COB limit the product's performance development from a technical standpoint. Flip COB, as an upgraded version of conventional COB, further enhances reliability, simplifies production processes, offers better display effects, provides a perfect near-screen experience, and achieves true chip-level spacing, reaching Micro levels. It also outperforms traditional SMD products in terms of high brightness, high contrast, black consistency, and display stability. Since COB screens cannot sort individual LEDs for similar optical performance like SMD screens, they require whole-screen image calibration before leaving the factory.

Flip COB

As industry technology advances, the cost of COB packaging is also trending downward. According to industry data, the P1.2 COB prices have already fallen below those of SMD technology products, and the price advantage becomes even more evident in smaller pitch products.

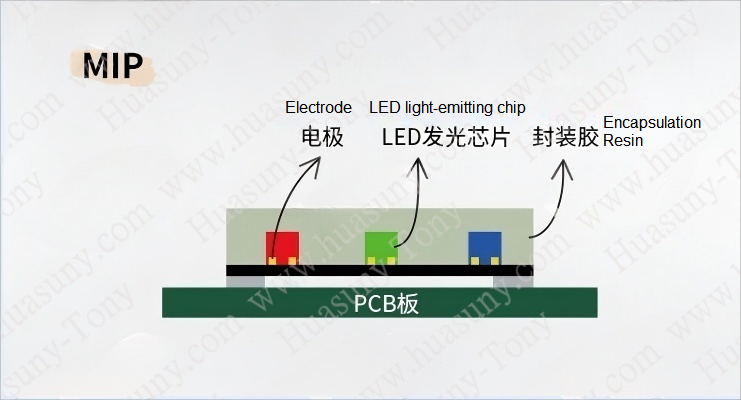

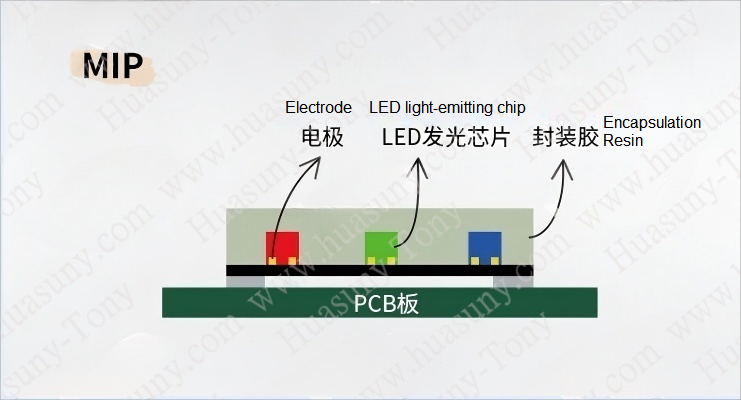

What is MIP?

MIP, which stands for Mini/Micro LED in Package, refers to cutting the light-emitting chips on an LED panel into blocks to form single or multi-chip devices. After sorting and mixing the light, they are welded onto a PCB board using SMT solder paste to form an LED display module.

This technological approach embodies the concept of "breaking down the whole into parts," with the advantages of smaller chips, lower losses, and higher display consistency, offering the potential to reduce costs significantly and increase production volume, thereby enhancing the performance and efficiency of LED display devices.

MIP

The MIP solution achieves color consistency through full pixel testing and mixing of BIM, reaching cinema-grade color gamut standards (DCI-P3 ≥ 99%); it also screens out and eliminates defects during the sorting and color separation process, ensuring the quality of each pixel point during the final transfer, thus reducing repair costs. Moreover, MIP offers better compatibility, suitable for different substrates and pixel pitch applications, and is compatible with medium and large-size Micro LED display applications.

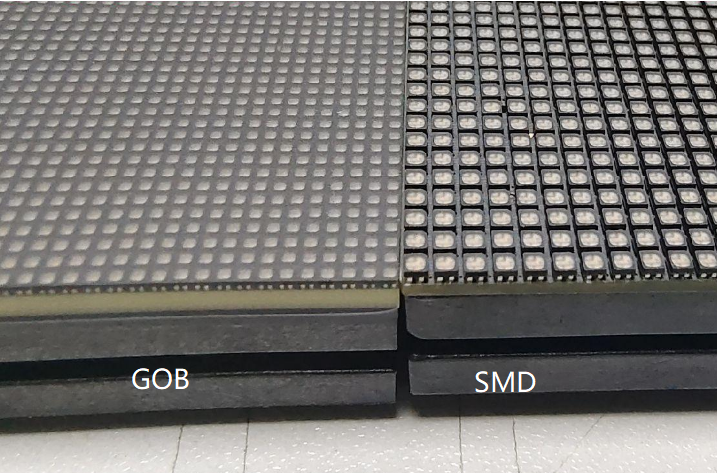

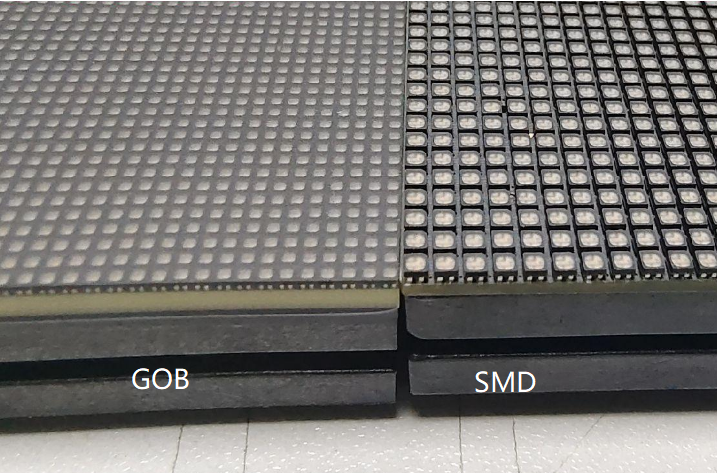

What is GOB?

GOB, which stands for Glue on Board, is a product of the higher demands people have for product quality and display effects, commonly known as surface gluing.

GOB

The emergence of GOB meets market demands and has two major advantages: First, GOB offers an ultra-high protection level, capable of being waterproof, moisture-proof, impact-resistant, dust-proof, corrosion-resistant, blue light-proof, salt-proof, and static-proof; Second, due to the frosted surface effect, it achieves a display transition from point light source to surface light source, increasing the viewing angle, enhancing color contrast, effectively eliminating moiré patterns, reducing visual fatigue, and achieving a more delicate display effect.

GOB vs SMD

In summary, SMD, COB, and MIP, the three packaging technologies each have their strengths and weaknesses. However, choosing the appropriate technology is crucial for different application scenarios and requirements. Huasuny offers a full range of products and holds multiple international and domestic patents. It has rich project experience in LED small-pitch display and is committed to empowering more scenarios with a richer and smarter new display product matrix. Huasuny's products are widely used in various industry fields such as command centers, surveillance and security, commercial advertising, sports competition, home theaters, and virtual shooting.